Aluminium Mesh Sheets (Aluminum Mesh Panels)

The structure of aluminium mesh sheet and panels include woven mesh, crimped wire mesh, expanded metal, and perforated metal, etc.

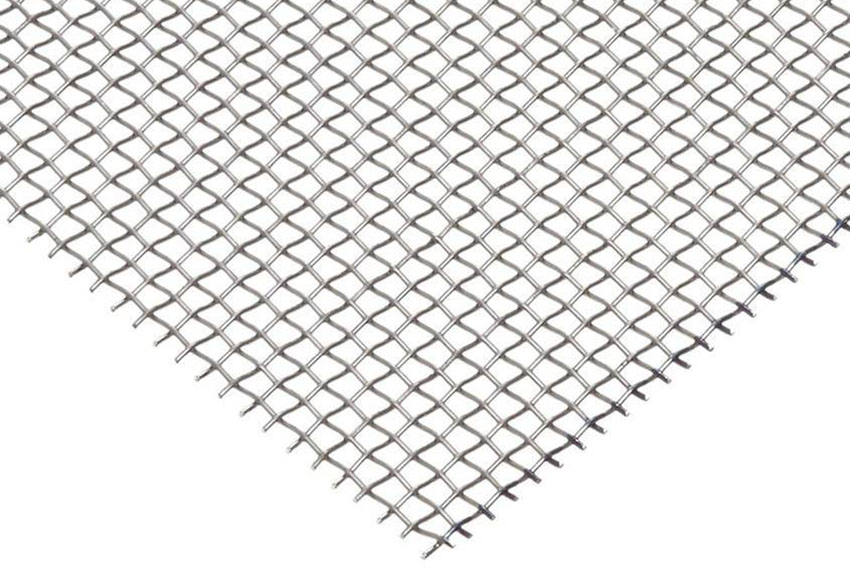

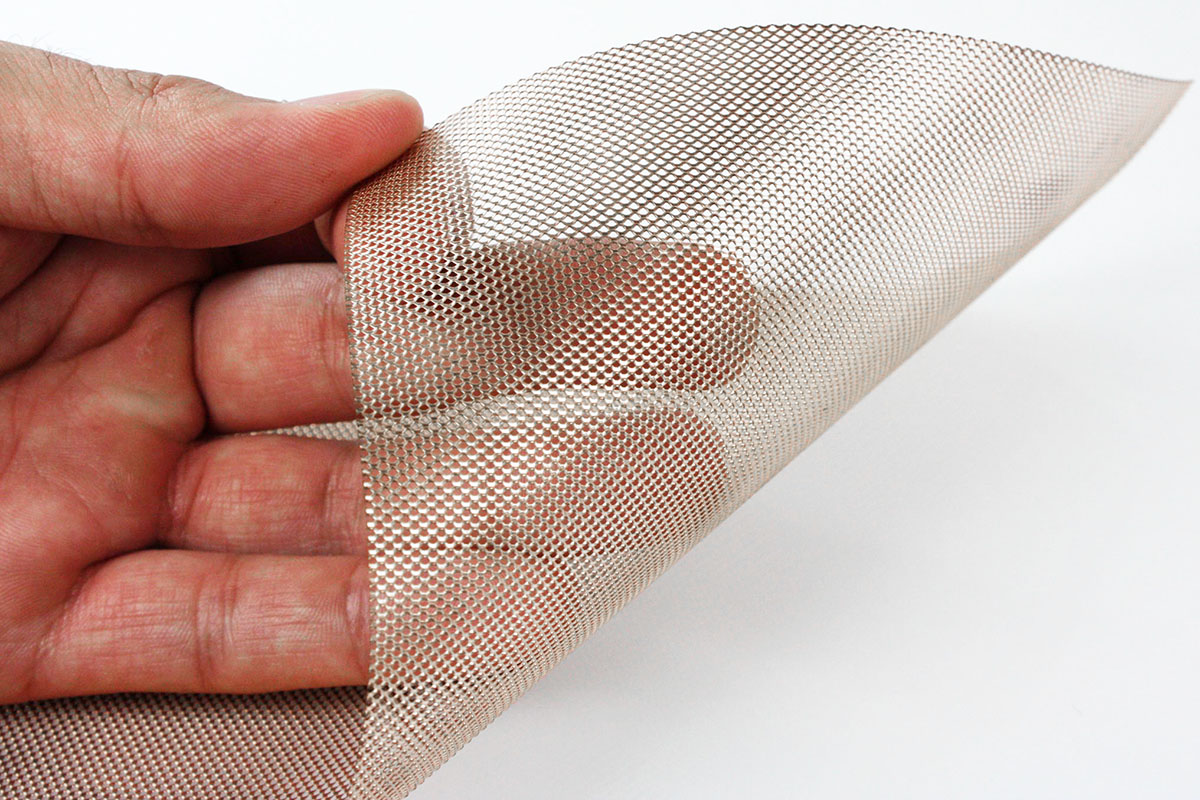

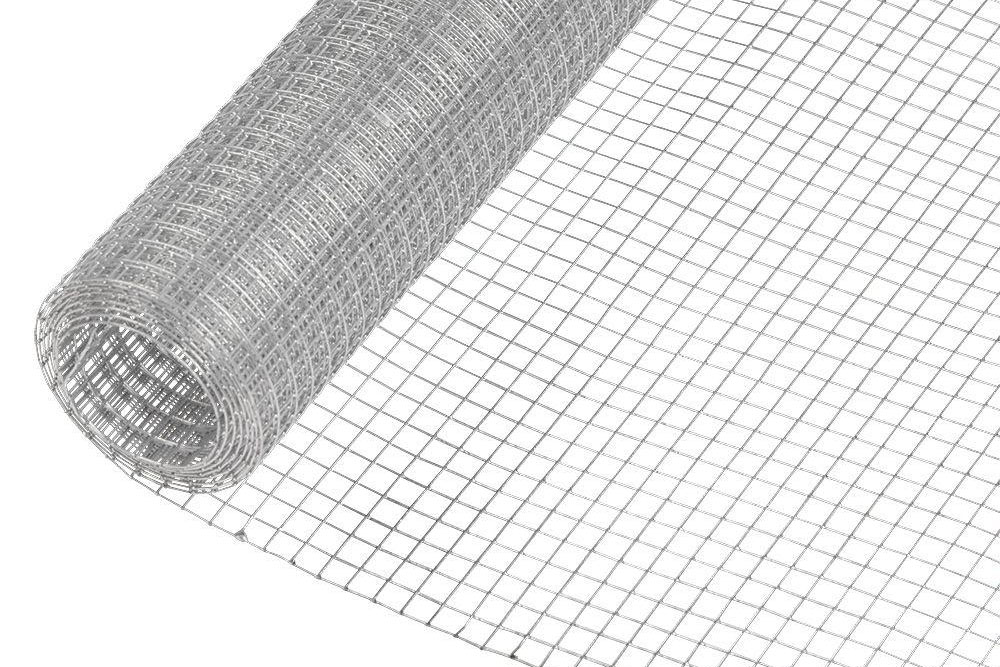

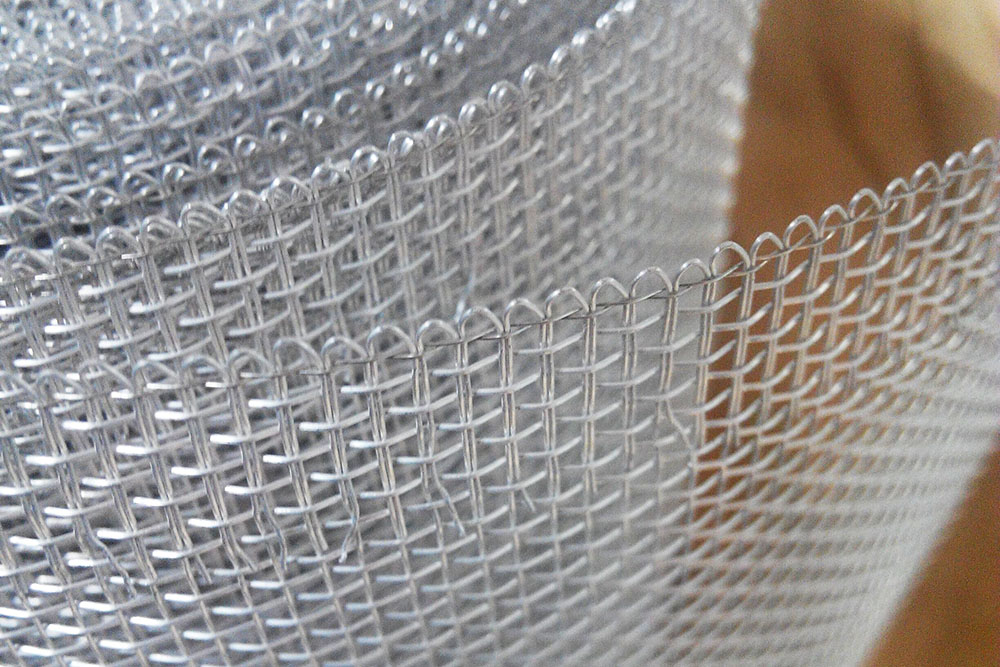

Aluminium woven mesh sheet: it is woven from aluminum wire by a loom machine, the weaving method is generally plain weave, and the mesh opening is usually square. Fine aluminum mesh is usually used for filtering, sieving, or window screens for mosquito control.

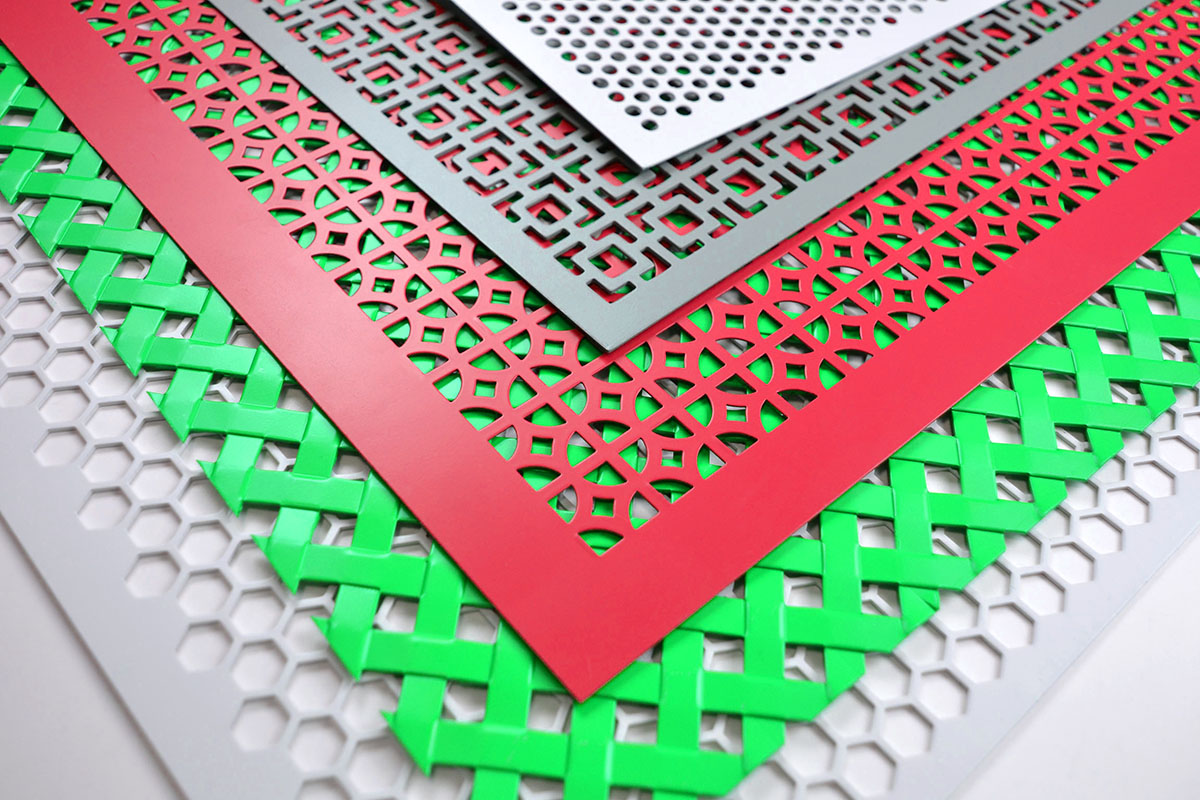

Perforated aluminium mesh sheet / panel: it is a metal sheet or plate with a series of holes perforated by a punching machine on the aluminum plate. The hole shape are various such as round, square, round end, slot, star or other decorative hole patterns. Round hole is the most common and economical one.

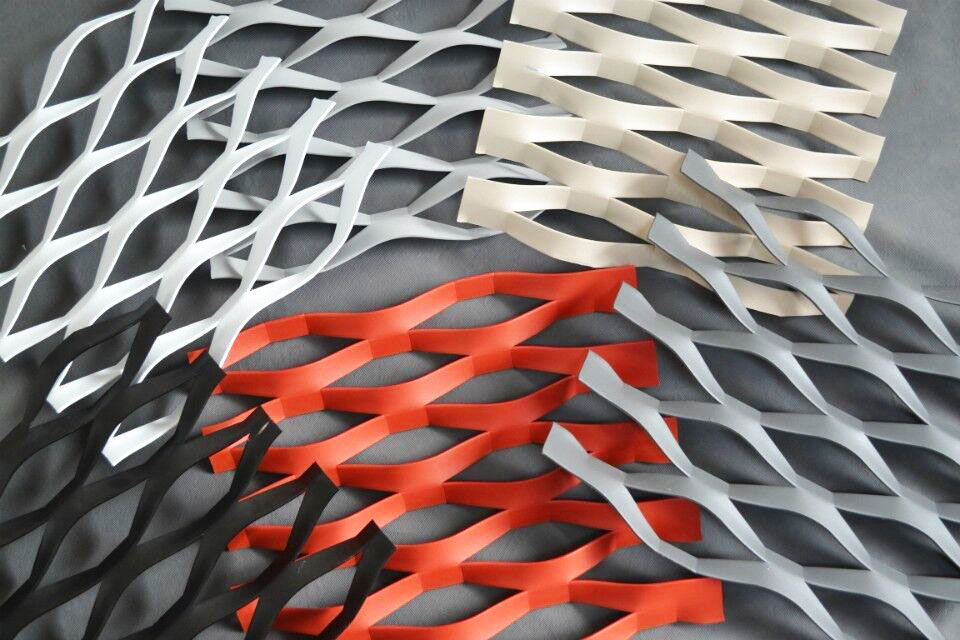

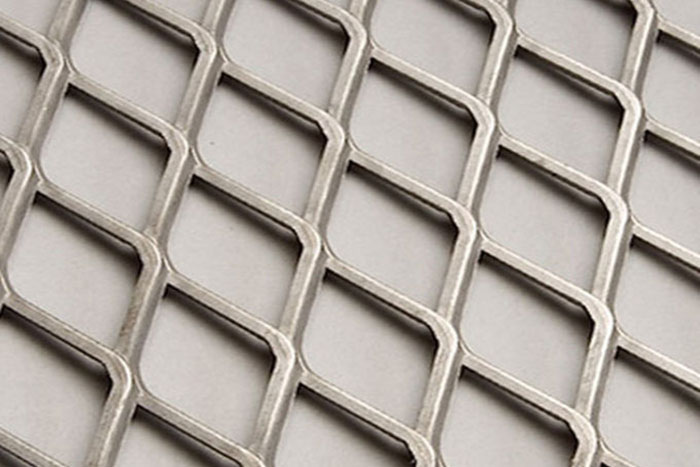

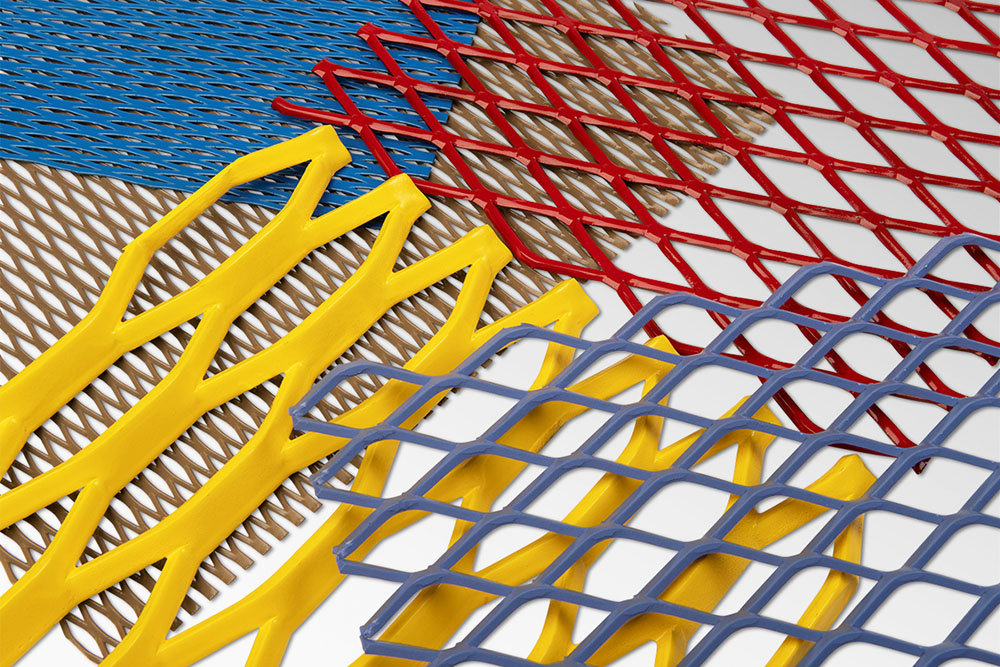

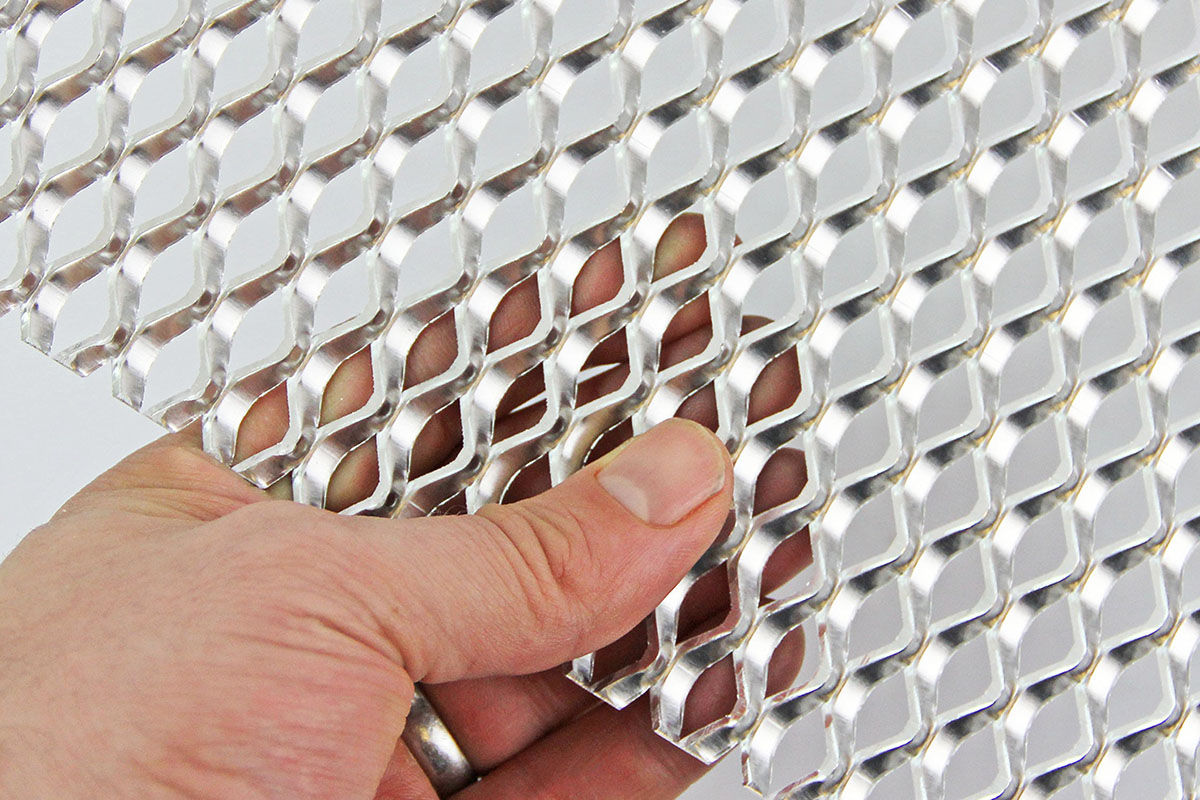

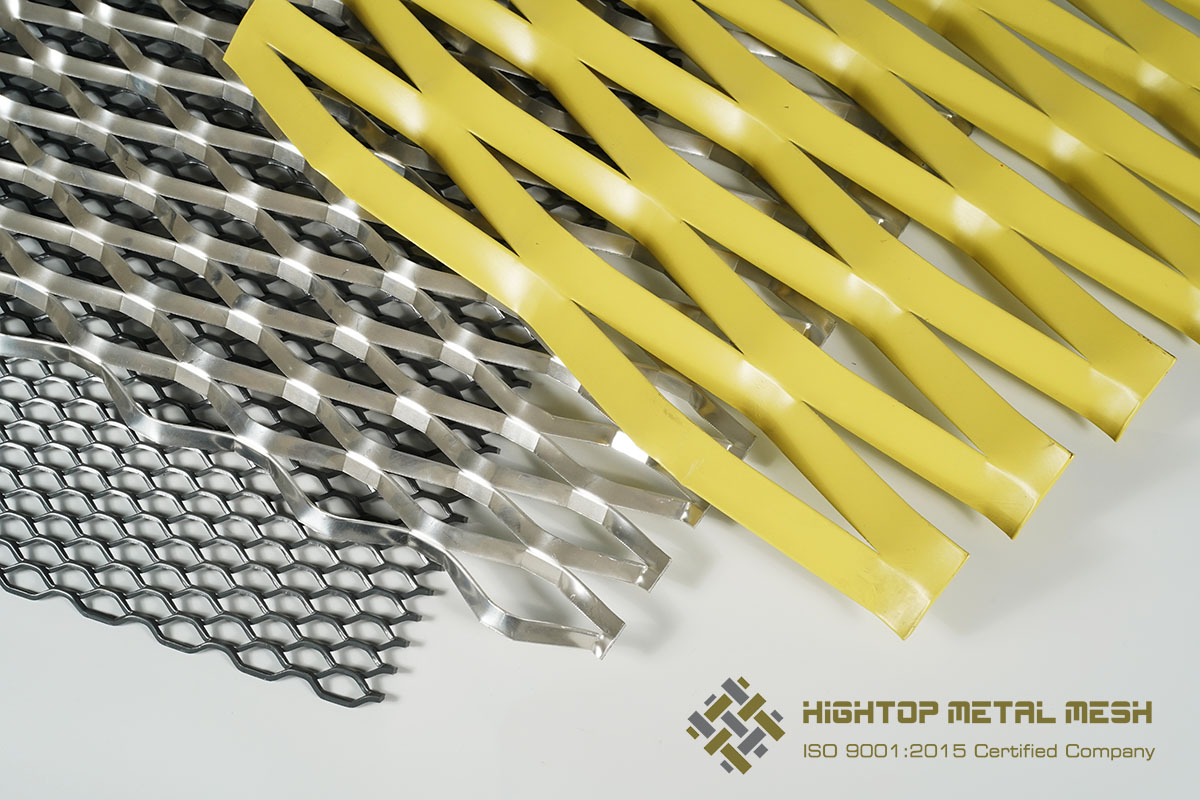

Expanded aluminium mesh panels: It is a series of diamond-shaped opening formed by cutting and stretching on an aluminum plate. The opening of the mesh panel that is processed for the first time is raised, and then flattened by a roller press to form a mesh sheet with a flat surface.

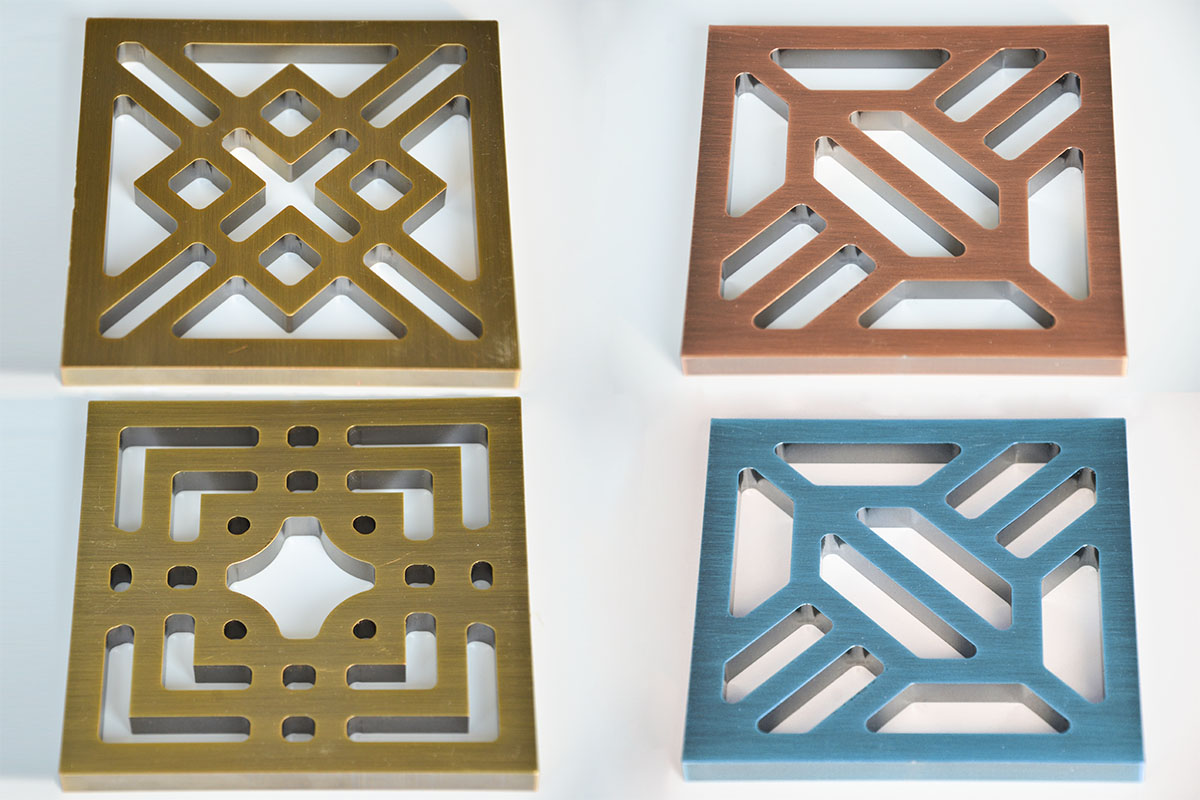

Aluminum laser cut mesh panels: It is a metal mesh panel that is cut into various patterns on an aluminum plate by a CNC laser cutting machine. Compared with perforated mesh, the laser cut mesh can have various complicated patterns and has high precision, neat edges and other advantages.

Applications of Aluminium Mesh Sheet Panels

- Window and door screen to prevent mosquitoes, flies and insects from entering.

- Experimental screens in the petroleum and chemical industries.

- Filters in the natural gas, oil industries.

- Security screen of doors and windows to improve the safety

- Interior and exterior decorations, such as building facades, wall cladding, car grilles, ceilings, partitions, shelves.

- Fence for railways, highways and airports

- Sidewalks, floors, and load-bearing grilles

- Stair railing, handrail, etc.